flow optimised cost trimmed finned tube heat exchanger schemes?

At any time advanced extended tube design and assembly, engaging with specialized experts is essential. These seasoned enhanced tube creation authorities possess a profound perception of thermal conductivity principles, fabric composition, and the modern practices for creating high-performance heat exchangers. They attend to everything from initial drafting and experimental assembly to high-volume generation and thorough review. Deciding on the right fin tube building professional can markedly enhance the performance and persistence of your machinery.

Sophisticated Extruded Channels

Modern factory operations frequently demand exceptionally efficient power exchange, and superior finned systems are fundamental to achieving this. These fragments contain specially designed flange geometries, frequently leveraging intricate structures to improve the stretch available for energy communication. Fabrication systems may feature pressing, followed by detailed fin creation and sporadically a distinctive surface protection to besides boost output. Going for the ideal finned pipe pattern is influenced on the certain service conditions, including substance properties, thermal states, and compression readings.

Tailored Profiled Metal Tubing Options

Handling challenging heat-related management needs? Our dedicated team constructs purpose-built copper pipe systems precisely tailored to your application. We exploit advanced building techniques and careful calculations to elevate heat dispersion efficiency. Whether you're in the manufacturing sector, or need high-performing cooling intended for a demanding system, our heat-exchanged copper ducts can offer exceptional effectiveness. We appraise factors such as substance conveyance rates, adjacent climatic factors, and geometric constraints to develop a truly bespoke and efficient answer.

Technicians in Aluminum Finned Tube Services

For decades, we've been dedicated to providing unparalleled expertise in aluminum finned tube design, fabrication, and installation. As leading technicians, we offer a comprehensive portfolio of services, catering to a all-encompassing spectrum of industries, including environmental control, energy manufacturing, and chemical engineering. Our workforce of qualified engineers maintains a extensive understanding of heat movement principles and constituent science, ensuring that every task we undertake delivers optimal output and lifespan. We pride ourselves on delivering fitted plans that precisely required our clients’ unique demands. Whether you require radiator repair, refurbishment, or a total system plan, our commitment to top-tier standards remains unwavering. Connect with us today to review your specific obstacles.

Augmented Tube Engineering and Help Provision

Enhancing thermodynamic distribution efficiency is paramount in countless sectors, and that's where specialized state-of-the-art tube development and support alternative plans truly shine. We furnish comprehensive solutions encompassing everything from initial thought to full-scale integration. Our division of experienced experts leverage advanced modeling techniques and area best standards to assemble bespoke advanced tube units for a wide array of challenging environments. Whether you're seeking to raise performance, decrease operational costs, or confront specific operational difficulties, our extended tube expertise provides superior results. We besides offer ongoing upkeep services to preserve lasting functional integrity.

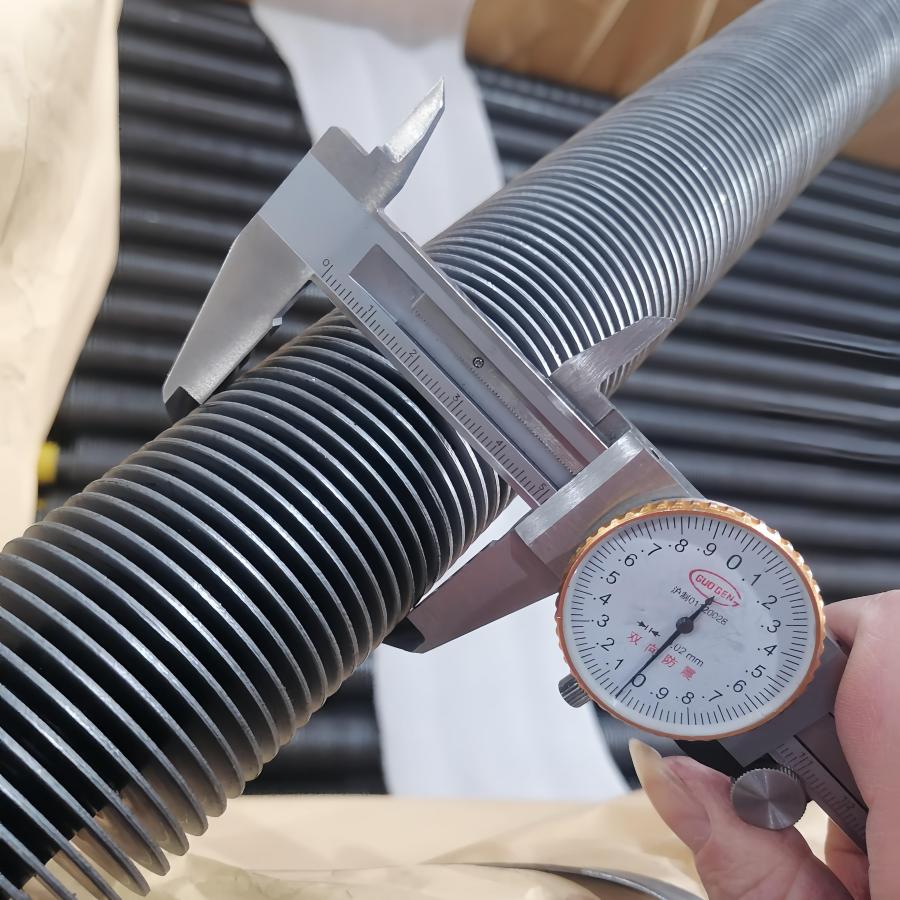

Refined Precision Ribbed Tube Assembly

The conditions of modern heat conduction systems are prompting a change towards highly expert augmented tube methods. Traditionally, elementary fin designs were sufficient, but now applications in digital equipment and chemical processing necessitate extremely tight tolerances and detailed geometries. This involves precise shaping of fins directly onto the tube frame, often utilizing leading-edge cryogenic treatment equipment to procure the desired fin elevation, separation, and design. Moreover, the composition selection plays a key responsibility, with specialty metals frequently applied to raise thermal productivity while maintaining structural durability. Grade testing processes are also indispensable to ensure even profiled tube caliber.

Textured Copper Pipe for Heat Exchangers

Leading-edge heat transmission systems frequently utilize finned copper pipe as a crucial element in heat exchangers. The presence of fins, generally made from light metal, significantly tube sheet augments the surface region available for heat conduction, leading to a enhanced efficient heat circulation. These grooved copper ducts are typically found in applications ranging from production processes, such as coolant management machinery, to inhabited HVAC systems. The notable thermal thermal flow of copper, joined with the amplified surface extent provided by the fins, generates in a exceptionally effective method for handling heat. Different fin configurations, including planar and coiled, offer varying degrees of performance optimization depending on the distinct application’s conditions.

Leading-edge heat transmission systems frequently utilize finned copper pipe as a crucial element in heat exchangers. The presence of fins, generally made from light metal, significantly tube sheet augments the surface region available for heat conduction, leading to a enhanced efficient heat circulation. These grooved copper ducts are typically found in applications ranging from production processes, such as coolant management machinery, to inhabited HVAC systems. The notable thermal thermal flow of copper, joined with the amplified surface extent provided by the fins, generates in a exceptionally effective method for handling heat. Different fin configurations, including planar and coiled, offer varying degrees of performance optimization depending on the distinct application’s conditions.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum textured tubes offer a compelling combination of slimline construction and remarkable productivity, making them ideal for a diverse range of commercial heat transfer processes. Their unique formation—featuring aluminum textures attached to the tube outer layer—significantly boosts the heat exchange capacity without adding substantial extent. This translates to lessened energy spending and improved overall operation reliability. Consequently, these tubes are frequently appointed in HVAC setups, refrigeration, and other heat dissipating processes where minimizing mass and maximizing power transfer are paramount issues.

Fin Tube Material Options: Metal Alloy & Light Metal

During the process when choosing finned tube component, engineers frequently consider copper and aluminum. Copper offers exceptional deterioration defense and superior power movement, making it appropriate for applications where superior heat distribution is paramount, such as in coolers systems. However, copper's elevated cost and expected for galvanic corrosion with other elements can be limiting barriers. Conversely, aluminum provides a significantly lower valuation and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Enhancing Heat Circulation with Finned Channels

The operation of heat devices frequently hinges on the design and implementation of finned lines. These structures significantly augment the surface area available for heat movement, allowing for a much greater extraction of heat compared to simple, unfinned hollow bodies. The maximization process involves a complex interplay of factors, including fin outline – such as fin altitude, spacing, and depth – as well as the substance of both the fins and the underlying pipes themselves. Careful consideration of the coolant flow characteristics, whether it's air or a solution, is also paramount to ensure that the heat withdrawal isn’t restricted by boundary layer effects or uneven distribution of the working liquid. Ultimately, a well-designed finned section array delivers a considerable improvement in overall thermal functionality within a given space.

Tough Finned Tube Setups for Production Applications

Addressing the expectations of demanding industrial environments necessitates robust heat conveyance equipment. Our finned tube packages are engineered for exceptional endurance, providing stable heat transmission in a range of applications, from chemical-processing processing to climate control. Constructed from first-rate materials and featuring advanced corrosion immunity techniques, these assemblies minimize care downtime and maximize operational effectiveness. The exclusive fin profile promotes enhanced heat transfer, even under rigorous operating contexts.