Is customized reporting crucial Are tube polishing machines adaptable to changing production volumes

Motor vehicle companies demand the highest criteria of precision in components. A critical aspect is achieving a spotless coating on sunken sections, which can be tough with traditional methods. Our advanced Precision Dished EndAC Polishing Machine fulfills this obligation by providing an robotic and exact remedy. This apparatus harnesses advanced tooling and a regulated polishing procedure to produce a silky finish on concave edges, ensuring optimal performance and hardiness of automotive units.

- The machine’s programmable controls provide for precise changes to the polishing specifications, assuring steadiness and replicability.

- Its space-saving design amplifies workspace functionality while easing operator fatigue.

- Incorporation with existing manufacturing methods is direct, streamlining production pipelines.

Next-Generation Tank Polishing Machines for Stainless Steel Fabrication

In the sector of stainless steel assembly, obtaining a spotless and sparkling coating is indispensable. To realize this endeavor, high-efficiency tank polishing machines have developed as indispensable contraptions. These innovative machines exploit cutting-edge technology to efficiently extract surface imperfections and enhance a radiant sheen on stainless steel tanks.

- In addition, high-efficiency tank polishing machines are fabricated for optimal performance, including durable construction, strong motors, and groundbreaking polishing heads that diminish surface damage.

- Accordingly, fabricators can maximize exceptional results with minimal effort, accelerating their production procedures and yielding high-quality tanks that address the stringent demands of various branches.

Cutting-Edge Cylindrical Polishing System for Precision Engineering

The demand for exceptional surface quality in precision engineering is constantly increasing. To meet these rigorous requirements, a novel cylindrical polishing system has been established. This leading equipment adopts cutting-edge techniques to generate unparalleled surface refinement. It proficiently eliminates imperfections and upgrades the overall productivity of cylindrical units across a wide range of markets.

- Benefits include increased performance, reduced manufacturing charges, and improved product reliability.

- The system is constructed to handle a wide range of materials, including metals, ceramics, and plastics.

- Specialists can easily modify the polishing controls to obtain the desired coating.

This advanced cylindrical polishing system represents a significant progress in precision engineering, enabling manufacturers to produce units of exceptional merit and effectiveness.

Robotic CNC Polishing Solutions for Complex Shapes

Attaining a pristine polish on intricate elements can be a arduous task. Traditional polishing approaches often struggle to offer consistent results on complex shapes, causing time-consuming loops. However, the advent of intelligent CNC polishing solutions has upgraded the industry, helping manufacturers to achieve unprecedented levels of accuracy and efficiency.

These innovative systems exploit intelligent machining technology to rigorously level surfaces with minimal operator intervention. Equipped with multi-axis spindles and a variety of polishing tools, CNC machines can smoothly handle even the most demanding profiles.

As well, these solutions offer advanced control over settings such as pressure, speed, and tool path, guaranteeing consistent results across different materials and complexities.

- Pros of automated CNC polishing include:

- Boosted precision and surface grade

- Cut cycle times and production costs

- Enhanced product consistency and repeatability

- Broader design flexibility for complex shapes

Tough Tank Polishing Machine for Industrial Applications

For demanding industrial locations where efficiency is paramount, a heavy-duty tank polishing machine is an vital tool. These machines are specifically constructed to handle the challenges of continuously operation in demanding environments. Equipped with durable construction and high-torque motors, they can effectively extract rust, paint, and additional contaminants from tank surfaces, delivering a smooth and sanitary finish. A variety of attachments are available to accommodate different tank sizes and layouts, making them versatile for a wide range of applications.

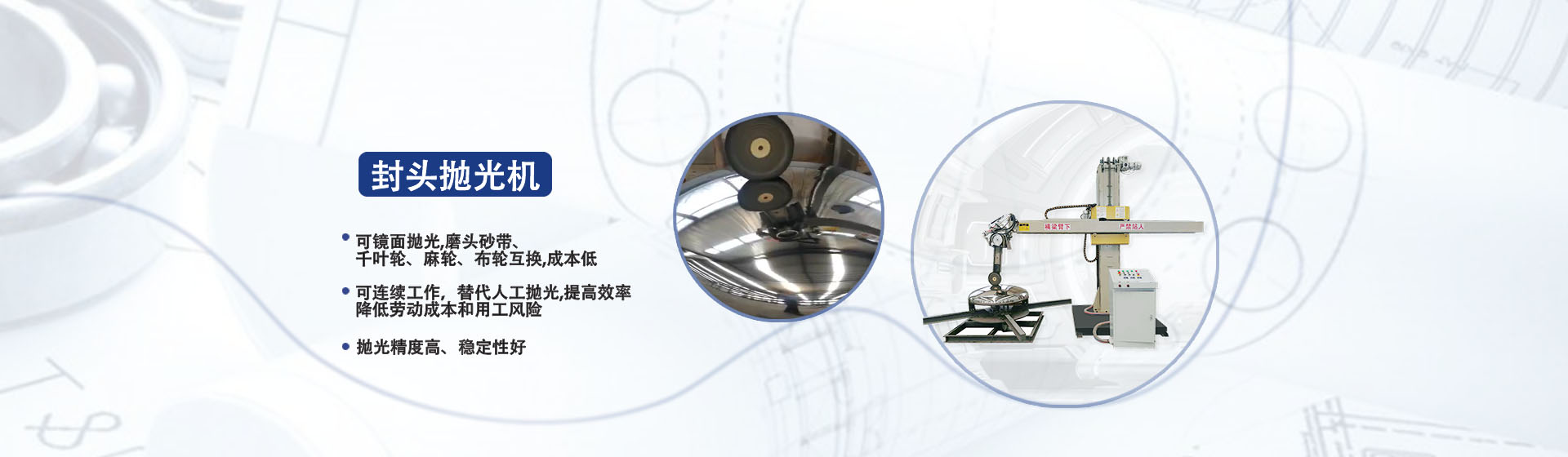

Adaptive Control-Equipped Dished End Polisher

Our cutting-edge Dished End Polisher implements smart Adaptive Control Technology to deliver unparalleled performance. This mechanism continuously analyzes the polishing process in real time, securing optimal surface quality for a wide range of objects. The Adaptive Control Technology streamlines the adjustment of key criteria, such as pressure, speed, and oscillation, to achieve uniform results every time.

- Merits include:

- Elevated surface finish quality

- Lowered polishing time

- Increased control over the polishing process

- Adaptability for a range of materials and applications

Computerized Polishing Unit for Superior Surface Treatment

A CNC polishing gadget is a powerful tool leveraged in various domains for generating exceptional surface finishes. These machines employ computer numerical control (CNC) technology to carefully polish surfaces, eradicating imperfections and achieving a smooth, refined appearance. The robust design of CNC polishing machines enables for varied output.

- Processing domains

- Metals

- Producing smooth coatings

The computer-controlled nature of CNC polishing machines provides uniform results, minimizing human error and optimizing efficiency. By deploying a variety of instruments, these machines can address a large variety of surface varieties and materials.

Large-Diameter Cylindrical Polishing Machines

Developing and treating large diameter cylindrical objects often requires specialized equipment. These machines are developed to meet precise dimensional tolerances on objects with significant girth, harnessing a variety of buffing agents.

The choice of cylindrical polishing equipment depends heavily on the specific purpose and desired outcome. Some common types include spin polishing systems, each offering distinct advantages for refining coatings.

- demands conditions cylindrical polishing machine demands preferences

- Fixtures are essential to securely hold large diameter pieces throughout the surface refinement process.

- Modulating abrasive intensity are critical for maintaining consistent results.

Ultrafast Dished End Polishing Machine for Mass Production

In present-day fast evolving manufacturing field, the necessity for productive high-volume production workflows is pivotal. To meet this requirement, manufacturers are utilizing cutting-edge technologies like high-speed dished end polishing machines. These leading equipment deliver exceptional clearness in a time-sensitive manner, ensuring consistent quality and superior surface finishes for a broad range of components.

Engineered to handle large production runs with exceptional speed, these machines use advanced polishing techniques to obtain the finish required for demanding applications. Essential features include high-speed spindles, intelligent control systems, and innovative finishing pads that work in synergy to maximize output.

Moreover, these machines often incorporate automation capabilities for increased results and reduced labor costs. This combination of speed, accuracy, and smart technology makes high-speed dished end polishing machines a vital asset for manufacturers seeking to optimize their production processes and follow the growing calls of the market.

Accurate CNC Polishing for Aeronautical and Medical Devices

In the critical fields of aerospace and medical device development, surface caliber is key. CNC polishing furnishes a highly exact and reliable method to generate the exacting textures required for these critical applications. By making use of advanced CNC machining technology, manufacturers can create surfaces with exceptional flatness, precision, and robustness. This process empowers the production of components that address stringent requirements for performance, reliability, and soundness.

- requirements expectations needs expectations requirements

- Besides, CNC polishing optimizes the rusting resistance and biocompatibility of ingredients used in aerospace and medical devices.

- Consequently, it plays a vital role in extending the lifespan and enhancing the effectiveness of these products.

Versatile Cylindrical Polishing System for Customization

Introducing a revolutionary concept to cylindrical polishing: the Modular Cylindrical Polishing System. This leading system provides unparalleled customization, adapting to your specific demands. With its flexible design, you can effortlessly adjust the polishing heads, materials, and parameters to get the precise finish for your cylindrical objects.

- demands expectations criteria