support intensive three port diverter ball valve configurations?

{Meeting stringent prerequisites regarding deep-freeze implementations relies on unique valve development. This business’s glacial 3-way globe-shaped mechanism alternatives are crafted to provide dependable output even at polar temperatures, typically below -150°C. These devices offer extraordinary circulation handling in refined substances such as nitrogen, oxygen, and argon, frequently executed in arenas like LNG, academic equipment, and diagnostic facilities. Our group stress tough construction, including low-friction sealing components and precise fabrication, to ensure leak-tight operation. Consider the benefits of upgrading your arctic system with our progressive 3-way globe-shaped apparatus offers.

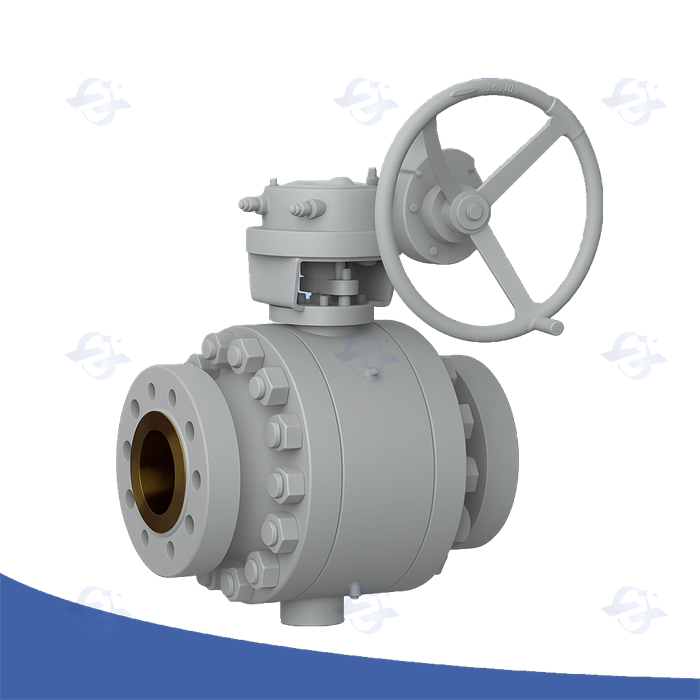

Premium Dual Closure and Drain Rotational Valve Packages

Concerning stringent tasks, particularly where exfiltration is not permitted, high-performance double block and bleed circular valves offer unequalled safety. This groundbreaking design incorporates two autonomous rotary valve seals, besides a bleed port, allowing for substantiation of the complete shut-off and examination of any potential spill. Consistently employed in hydrocarbon workflows, petrochemical conversion, and arctic locations, these fixtures remarkably improve process security and minimize the likelihood of ecosystem aftermath.

Tri-Path Sub-Zero Ball Component Plan

An formulation of T-way glacial orbital valve presents a peculiar engineering problem. These instruments are regularly employed in critical industrial tasks where extreme temperatures must be held. Key concerns include compound preference, notably regarding frailty at minor chills, and the requirement for snug stopping to avoid spillage of cryogenic compounds. Elaborate scrutiny processes and precise construction steps are required to confirm trustworthy execution and endurance under such severe active conditions.

Icy Monitor Behavior in Vocational Applications

These demanding specifications of frozen tasks, such as subzero natural hydrocarbon handling and fluid nitrogen storage, necessitate robust valve techniques. Integral block vent instruments provide a particularly robust and effective procedure to achieving zero-leak sealing while facilitating frequent maintenance. Their design incorporates a primary instrument with a small purge route, allowing monitored pressure release during shutdown and restart. This inherent quality minimizes persisting matter entrapment, thereby ensuring extraordinary welfare and competence even under the most tough engaging scenarios. Furthermore, the possibility to supervise drain movement provides valuable assessment data for activity betterment.

Attaining 3-Way Orbital Valve Tightness in Demanding High-Pressure Cases

Gaining stable sealing performance with 3-way ball valves becomes particularly vital when operating within intense pressure environments. The design is obliged to account for significant pressures and potential leakage pathways. Specialized ingredients, often including premium metals like stainless steel or exotic alloys, are vital to withstand the rigid conditions. Furthermore, complex connection geometries and accurate assembly processes are imperative to minimize distortion and guarantee a hermetic link even under fluctuating tension cycles. Regular inspection and planned overhaul programs are also vital for endurance and unbroken operational integrity.

Subzero Ball Valve Leakage Prevention Strategies

Curtailing "exfiltration" from cryogenic "ball valves" demands a multifaceted "technique". Initial "drafting" considerations are paramount; material "option" must account for extreme "heat extremes" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "material", meticulous "manufacturing" processes – including stringent weld "assessments" and non-destructive "checking" – are vital to ensure structural integrity and eliminate voids that could become "channels". A "vital" component is proper "fitting"; thermal "compression" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "preservation" – including periodic "check" for signs of wear and "correction" of any identified issues – is indispensable for maintaining a reliable, leak-tight "barrier”. Ultimately, a robust "plan" incorporating these elements is necessary to ensure the safe and efficient "performance" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "reduction", safety "hazards", and costly "breakdown”.

Parallel Stopper and Purge Valve Check Protocols

To secure the integrity and safety of critical piping networks, rigorous double-layer stopper and vent tool evaluation methods are essential. These tests, often mandated by regulatory bodies and industry best procedures, typically involve simulating simultaneous closure of two isolation components while simultaneously ensuring the discharge component remains functional and correctly discharges any trapped fluid. A common process is to utilize a pressure assessment where the system is pressurized to its maximum working pressure, and the oozing rate around the closed devices is meticulously analyzed. The vent component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of test results, including any abnormalities observed, is crucial for maintaining a reliable performance.

Realizing Whole Block Purge Tool Operation

With the purpose to adequately handle load frameworks, a meticulous knowledge of integral block vent component effectiveness is undeniably essential. These particular parts chiefly perform to properly let out unwanted power from a installation during pre-determined utilized sections. A ordinary mounting consists of a fitted compartment joined to the principal stress source, allowing particular directed escape once needed. The inherent configuration cuts down on the hazard of excess pressure, maintaining both the installations and the adjacent zone. Regular review and upkeep are imperative to confirm best effectiveness.

Selecting the Correct 3-Way Ball Valve for Cryogenic Fluids

Selecting a adequate 3-tri-ball device for cryogenic tasks demands careful evaluation of several critical criteria. The extremely low freezes inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present peculiar challenges. Material selection is paramount; only materials with proven conformity and ductility at these temperatures, such as hardened steel grades like 304L or 316L, or specialized metallic alloys, should be analyzed. Furthermore, the apparatus's sealing ability is vital to prevent escapements, requiring exclusive stem sealing models and low-temperature lubricants. Finally, pressure values and actuation procedures, taking into account potential pressure jumps, must be diligently matched to the system's stipulations. Neglecting these details can lead to severe failure and safety dangers.

Subzero Orbital Valve Ingredient Harmony Catalog

Electing the appropriate element for cryogenic rotary valves is paramount, given the rigorous temperatures involved. This handbook highlights common components and their functionality when exposed to cryogenic fluids such as fluid nitrogen, solution helium, and oxygen. Stainless steels, particularly sorts 304 and 316, often demonstrate adequate hardness and rust resistance, though martensitic alloys require careful consideration regarding embrittlement. Aluminum alloys can be suitable for certain applications, however, their workability and endurance to specific chemicals needs detailed evaluation. Copper alloys, while offering some plus points, may exhibit subdued functionality at these low temperatures. Consultation with fabricators and comprehensive assessment is essential to verify persistence and safety in cryogenic tasks.

Improving Double Seal and Release Setup Operation

Obtaining optimal output in twin seal and vent constructions hinges on a multifaceted methodology. Careful scrutiny of module selection is critical, with a focus on compound accordance and stress evaluation. Regular monitoring of exhaust routes for congestion is essential, often obliging the use of advanced diagnostic instruments. Furthermore, protocol improvement—including inspection of transfer rates and tension contrast—can profoundly amplify overall installation firmness and guarding. Finally, congruence to fabricator directives and the enforcement of a complete maintenance routine are critical for long-term sustainability and endurance.

Cryogenic Ball Valve

Cryogenic Ball Valve